Recently added item(s)

No products

Recently added item(s)

No products

The group has chosen to invest in the development of the production departments in order to improve the quality standards of the products and the internal working processes. We have highly specialized machinery able to process different kinds of materials.

We continually invest in research and development to secure the constant improvement of our products and quality standards. All the products are designed and manufactured in strict compliance with the applicable quality and safety standards in Europe and in the rest of the world.

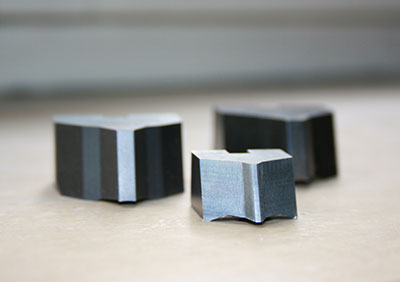

The tools department is characterized by vanguard machinery for the grinding of the tools. The inserts are realized with high quality material: ASP 2060, that guarantees reliability and the best slotting and keyseating machining results.

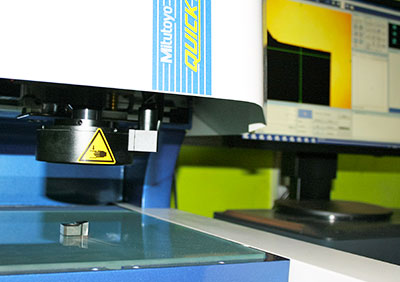

Before leaving the establishments, every tool is submitted to dimensional and functional tests. The metrology department is equipped with instruments able to carry out precise dimensional tests. The prepared personnel follow a strict quality control policy in order to guarantee high quality results.

The toolholders realized with high quailty material is the result of a special technical design. Thanks to the monolithic construction the bars allow rigidity and precision when cutting. The bars are available in two different models, one compatible with the tool holder block patented by Cabe, the other compatible with traditional holder blocks for slotting machines.

The high quality of our tools and of all the BR1 products is guaranteed by the high level of the technical design, the choice of materials and by the implementation phase executed with meticulous dimensional and functional controls.